Graintec Recirculation Aquaculture System (RAS) philosophy

Landbased fish farming

We are constantly working to push the boundaries

Value engineering is important when designing RAS fish farms. It all starts with your idea, and together as one team, we design the fish farm so that it meets the demands on your market – not just today but also in the future. The design of RAS fish farms must be done with focus on system reliability and high-end value design and execution.

We will guide you through the whole process, ensuring a successful and well-working RAS project after handover.

Project phases

– we support you in every step through the whole project

Our RAS philosophy

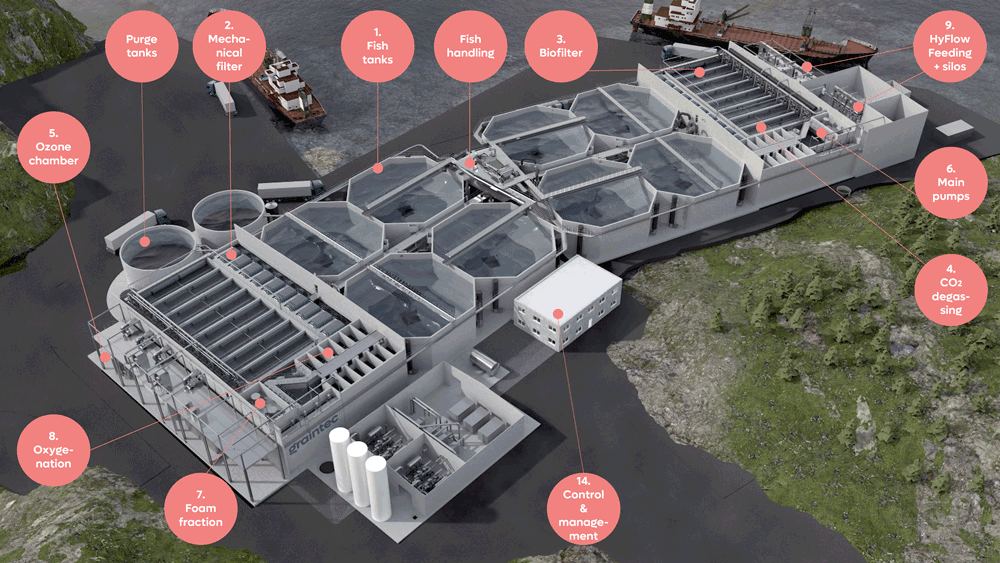

Removal of solid waste is paramount for maintaining high water quality and optimum fish welfare in recirculating aquaculture systems (RAS). Our RAS is designed to efficiently remove suspended solids through a series of water purification steps.

To promote optimum water flow and gentle fish handling our fish tanks are kept free of water intake pipes and mechanical feeding systems. This allows for easy movement of fish without emptying the fish tank of water avoiding discharge of expensive high-quality conditioned RAS water.

- Suspended solids down to 40-60 microns are effectively removed by mechanical filtration. Removing larger particles such as fish faeces and uneaten feed early in the water treatment process reduces the risk of accumulation of finer particles within the system and lowers the load on the down-stream biofiltration process.

Alongside oxidizing harmful nitrogenous waste to harmless nitrate our biofilters also allow particle settling to further enhance solids removal from the water. Our biofilters are designed to ensure the highest level of biological and operational stability. We offer solutions ranging from manual- over semi-automatic to full-automatic biofilter cleaning setups.

Our self-cleaning and low-maintenance bobble degasser is effectively removing CO2 without the risk of introducing dead zones. Our RAS design allows for the integration of the degasser directly on top of our biofilters thereby minimizing overall footprint and CAPEX.

Ozone is a powerful oxidizing agent that helps flocculate dissolved organic matter for efficient removal in the downstream foam fractioning process. Ozone effectively kills free bacteria and clears the water of coloring thereby ensuring crystal-clear water.

To keep energy consumption at a minimum we design our RAS plants with a minimum head loss. We pump the water only once using highly efficient submerged low head high flow pumps.

7. Proteins and other dissolved- and floatable organic matters are effectively removed from the water in our foam fractionator subsequently promoting better gill health. As water flows through the foam fractionator, suspended fines become entangled on the surface of the collected foam further improving overall water quality.

8. The oxygen needed to sustain fish growth and overall welfare is introduced to the water using medium head oxygenation (MHO). The MHO is highly efficient while handling large water flows at a low head loss. An additional benefit of the MHO is its ability to strip the water of carbon dioxide and nitrogen while introducing new oxygen.

9. Our patented water-borne feeding solution HyFlowTM provides highly gentle transport of high volumes of fish feed to each fish tank. The solution is very versatile and provides continuous feeding to each fish tank both as surface and underwater feeding. Read more here..

Design focus:

Our many years in the fish feed business we have seen how the Aquaculture segment has developed for many decades and therefore we understand for your business and future.

Graintec standard solutions for Recirculated Aquaculture Systems (RAS) are based on two degrees of recirculated.

Intensive RAS = 300 – 500 liters of make-up water per kg. of fish feed

Super Intensive RAS = 30 – 300 liter of make-up water per kg. of fish feed

We ensure:

> The production fits to your marked and business plan

> Production plan and logistic

> Fish welfare

> Water parameters

> Fish feed logistic

> Biosecurity

> Preventing H2S

> Daily handling of fish

> Work environment

Fully integrated feeding system at the RAS farm ensures gentle feeding and optimum fish welfare.

All the way through the feed supply chain from the feed factory to the farm, efficient delivery of the feed with minimum waste must be guaranteed.

All our service and upgrade offerings are developed to provide seamless and optimised fish production.

We have developed and implemented a comprehensive Best Practice Project Execution model.

Have a specific need?

We look forward to hear your visions and thoughts. Please fill in the form below and we will get back to you very soon.

You are also welcome to contact the sales manager directly.