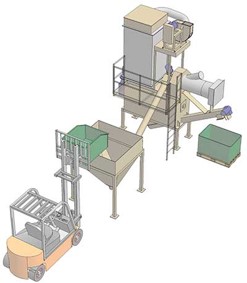

Recycling system

Recycling System for extrudet products

We are constantly working to push the boundaries

In pet food and aqua feed plants the extruder is stopped for size and recipe change this means that the start and the end of the production is not used for finished product.

This start up/stop material do have a high water activity and cannot be stored without drying and bringing the water activity down to avoid bacterial growth.

Recycling system

Design focus:

The product is delivered to the system from a delivery chute into a mixing/drying chamber. The drying takes place in the mixing chamber where a disintegration of the startup mass takes place together with hot air drying. The hot air is produced by a heat exchanger. The exhaust air is treated in the local odor reduction system. The finished dried powder Is transferred to the rework silo.

Drying and mixing time, air temperature is controlled by the integrated control box.

System based on:

> Intake conveyer

> A mixing using hot air for drying

> Heat exchanger for heating up the drying air

> Fan for the drying air

> Filter

> Separate control system

Share your ideas

We are looking forward to hear about your ideas and visions – we will do our best to support you and deliver the most optimum solution.

Fill in the form and we will get back to you very soon.

Headquarter

Denmark

Contact:

info@processintegration.dk

Phone +45 8686 2525